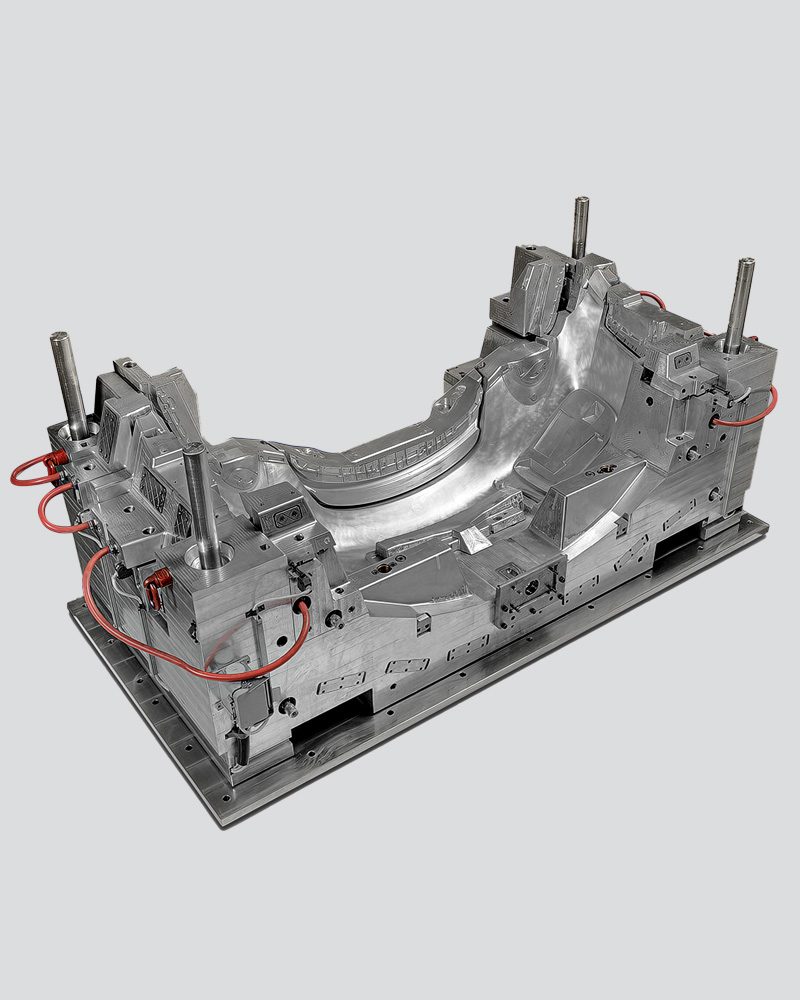

Model Stampi began as a manufacturer of thermoplastic molds, specializing right from the start on small, medium and large sized prototype aluminium molds for car interiors and exteriors.

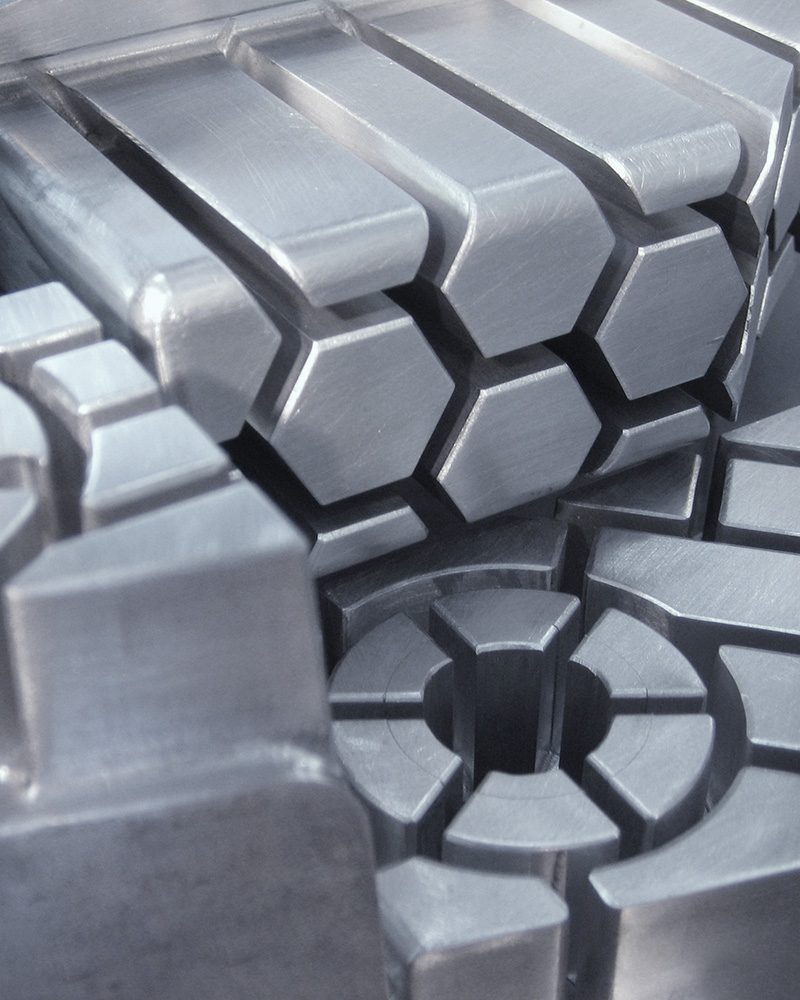

Over the years we have gained experience in bi-material and tri-material molds, molded on rotary presses, with blade technology, on single-component presses with external die or with movement of the molded part via robot.

We also create single-component prototype injection molds with co-injection of various types of metal inserts and over-molding of fabric and films.

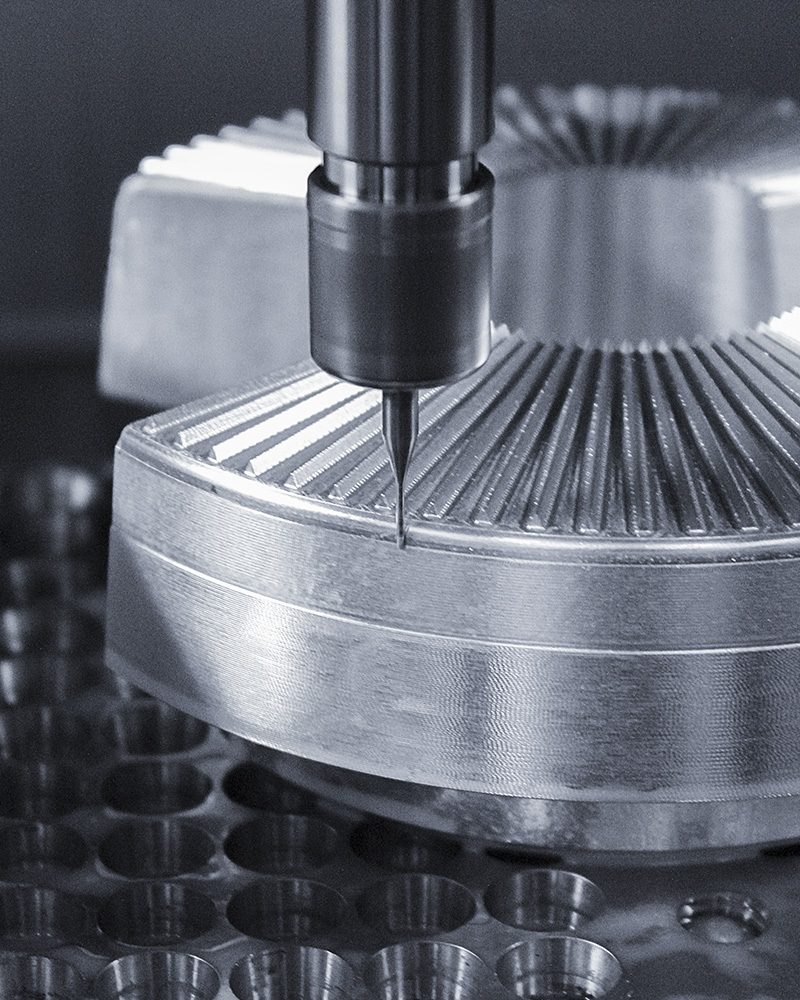

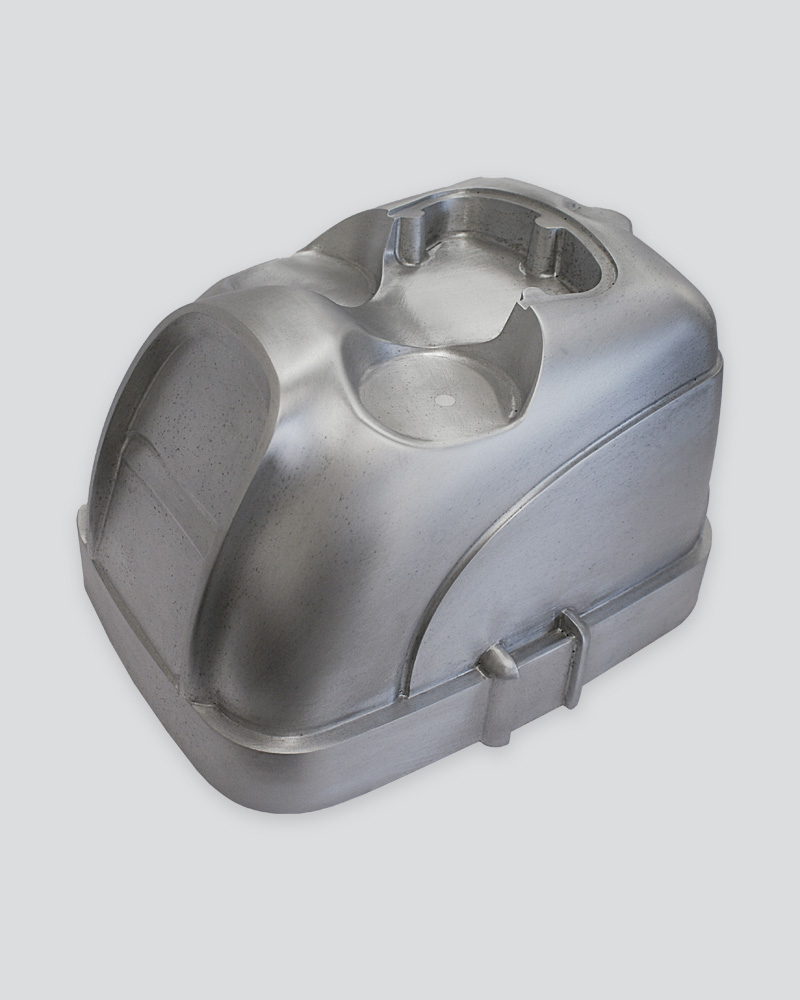

Model Stampi designs and builds thermoplastic molds for small and medium series production, offering aluminium injection molds or steel injection molds depending on the polymer used and the required mold life cycle.

We create aluminium and steel molds, of small to large dimensions (up to 2500 x 1500 mm), providing the customer with a complete service that goes from concept to mass production.

PUR/RIM technology is used for the production of parts and components in polyurethane, a thermosetting material known for its resistance and versatility.

Over the years we have specialized in the construction of PUR/RIM molds, significantly deepening our knowledge of this technology and becoming a reliable partner for customers who use these materials.

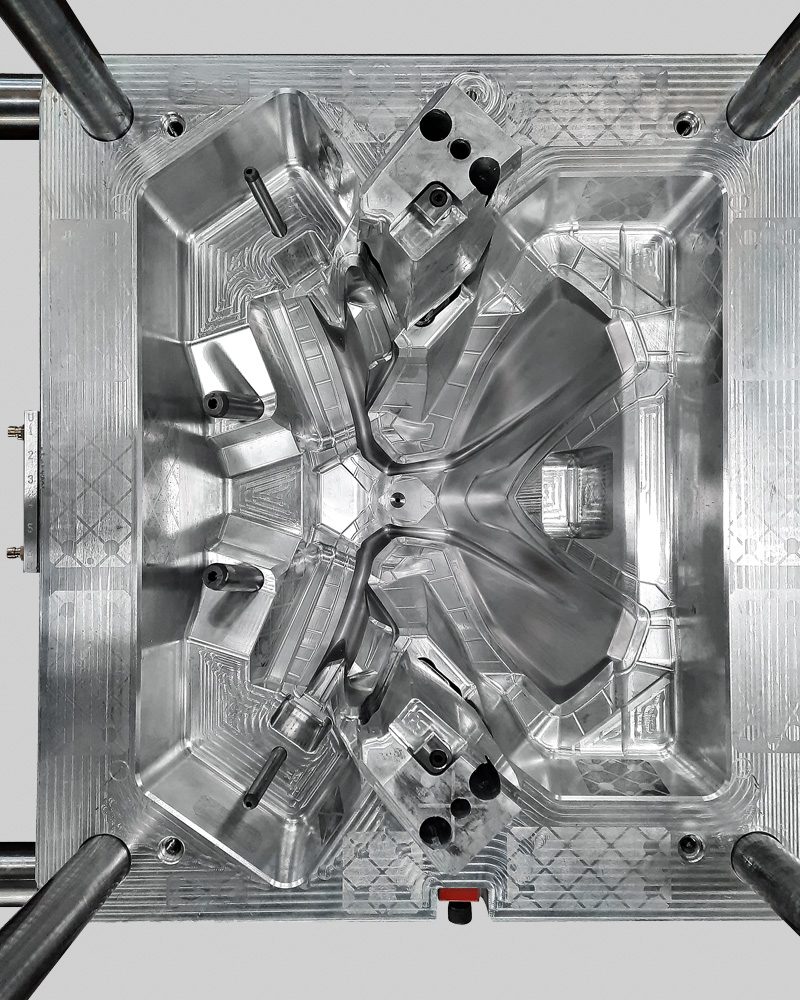

In particolare, Model Stampi è un punto di riferimento per la progettazione e realizzazione di stampi ad iniezione per paraurti ad alto contenuto tecnologico e da un’estetica di alto livello. In particular, Model Stampi is a point of reference for the design and production of injection molds for highly technological, aesthetic bumpers.

Model Stampi designs and manufactures blow molds, in particular for air ducts and tanks of various types.

Blow molds are used for the creation of hollow objects: the process consists of blowing compressed air into a hollow mold, allowing the object to conform to the shape of the internal walls of the mold.

Thanks to a decades-long collaboration with Modelleria Tardivo, we also create molds for thermoforming in cast or solid block aluminium, starting from the production of the model.

Thermoforming is a technique for hot molding of plastic materials, starting from plates or sheets, under pressure or vacuum, and is particularly suitable for making extremely thin plastic components or complex unusual shapes.

The latest technology to arrive at Model Stampi is carbon fibre, with its important particularities such as high mechanical resistance, excellent thermal insulation, resistance to temperature variations and chemical agents.

At Model Stampi we design and create injection molds in aluminium for carbon fibre.

© 2023 Model Stampi srl P.IVA 03448530265